As plating is finished, the dry film is taken off plus the uncovered copper not protect by tin is etched absent, leaving only the traces, pads, and also other patterns around the plate. The remaining tin is then chemically stripped, leaving only copper in exact regions.

Cloning a PCB is frequently important for producing an item. Many PCB firms might require to produce a similar PCB throughout multiple locations to keep up with demand, replicating the identical board exactly in several spots. Utilizing a PCB clone ensures that the boards used in Every place are equivalent.

Issues scaling: Prototype boards is probably not appropriate for significant-scale manufacturing and should require further style and design function to get scaled up for mass output.

Certainly. Our production operation is specifically designed for reduced quantity generation. Pricing will likely be various for may differ quantity order.

The easiest way to stay away from these challenges is always to evaluate the PCB fabrication procedure over the design cycle. You can do this by utilizing design and style for manufacturability (DFM) procedures and examining the abilities within your PCB manufacturer in the design cycle.

SPI (solder paste inspection): SPI happens just after solder paste printing on PCBs and right before SMDs inserting on boards. An SPI machine scans the solder paste and compares its condition, measurement, thickness, and place Using the pre-enter parameters. The solder paste thickness have to drop in the choice of ±0.03mm of your SMT stencil thickness.

By Benefiting from these solutions, pcb manufacturer you'll be able to develop a PCB clone that is precisely how you want it to generally be.

If designers do not retain the fabrication process and limitations in mind during the structure method, fabricated boards could possibly be impacted in the subsequent parts:

Copyright infringement: Given that the creator of the PCB, you have unique rights to the design of your board, and anyone who replicates or copies it with out searching for your authorization may be topic to copyright infringement.

They have got a grid of holes that allow elements being inserted and related with out soldering. You will discover different sizes and colours of breadboards obtainable.

Holes are generally mechanically drilled utilizing multi-spindle drilling devices. Substantial spindle speeds and little drill bits make little vias. Backing laminates guidance thin or flexible boards. Laser direct imaging (LDI) ablates holes by scanning a laser.

A printed circuit board carries electrical circuits and will allow indicators and electrical power to be routed in between units. PCBs include several levels of fabric:

Location parts on the board: When each of the parts are gathered, put them over the prototype board in accordance with the circuit style and design.

In order to make the top use of DFM to protect against pointless time delays and extra production charges, you'll want to utilize a comprehensive and able PCB style and design Examination, including Cadence offers.

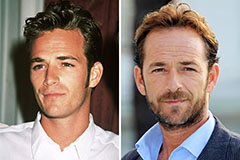

Luke Perry Then & Now!

Luke Perry Then & Now! Michael C. Maronna Then & Now!

Michael C. Maronna Then & Now! Sam Woods Then & Now!

Sam Woods Then & Now! Elisabeth Shue Then & Now!

Elisabeth Shue Then & Now! Bo Derek Then & Now!

Bo Derek Then & Now!